The manufacturing process of solar panels is experiencing substantial advancements throughout the 2020s. For example, the temperature required for Nordic Nano’s production process is notably lower than that of traditional silicon-based panel manufacturing, as the production line for material handling is conducted at room temperature, with the exception of the drying of nanomaterial, which occurs at this maximum temperature of 60°C.

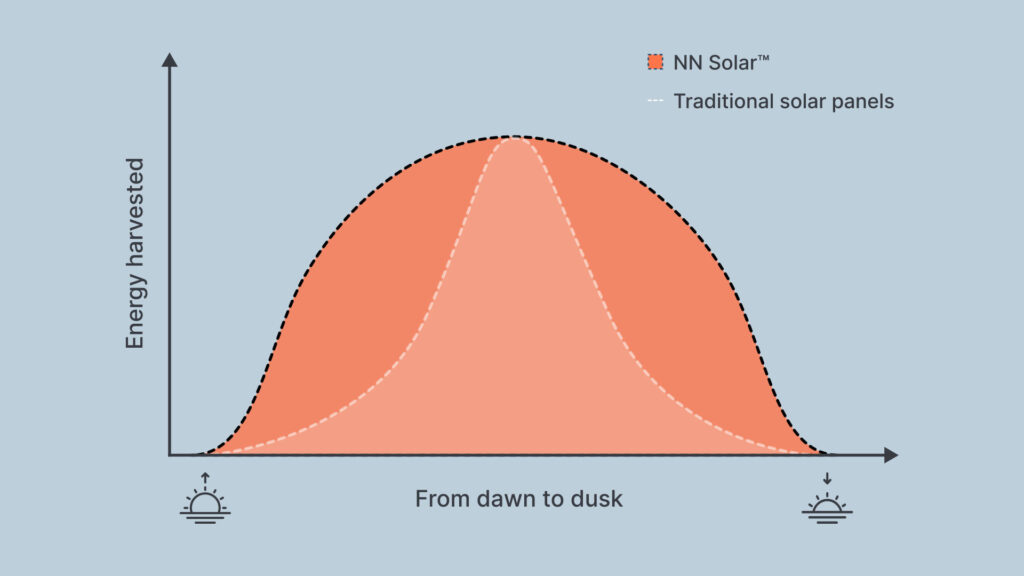

With Nordic Nano’s technology, it is possible to utilise solar radiation ranging from ultraviolet frequencies to infrared. It enables the capture of scattered solar radiation and opens a possibility to generate electricity from diffused light without needing precise alignment with the sun. This all demonstrates the significant potential of organic materials on various structural surfaces, and furthermore, energy can be produced even in cloudy weather from ultraviolet radiation and visible light frequencies.